Automation Systems

Time to enhance the old automation?

Old casters commonly have an outdated automation-structures and as a result these machines face a series of problems with concern to process control. These can have negative effects on product-quality, process stability and productivity.

Based on 20 years of experience in the design of continuous casting machines, ABAX can provide a full range of proven modular automation-solutions to boost the performance of your continuous casting machine. This can be a simple MMI for a low-cost solution up to a sophisticated system with Level-II product tracking functions.

The main targets of ABAX automation are:

- Improvement of product quality

- Improvement of process stability

- Improvement of casting-speed

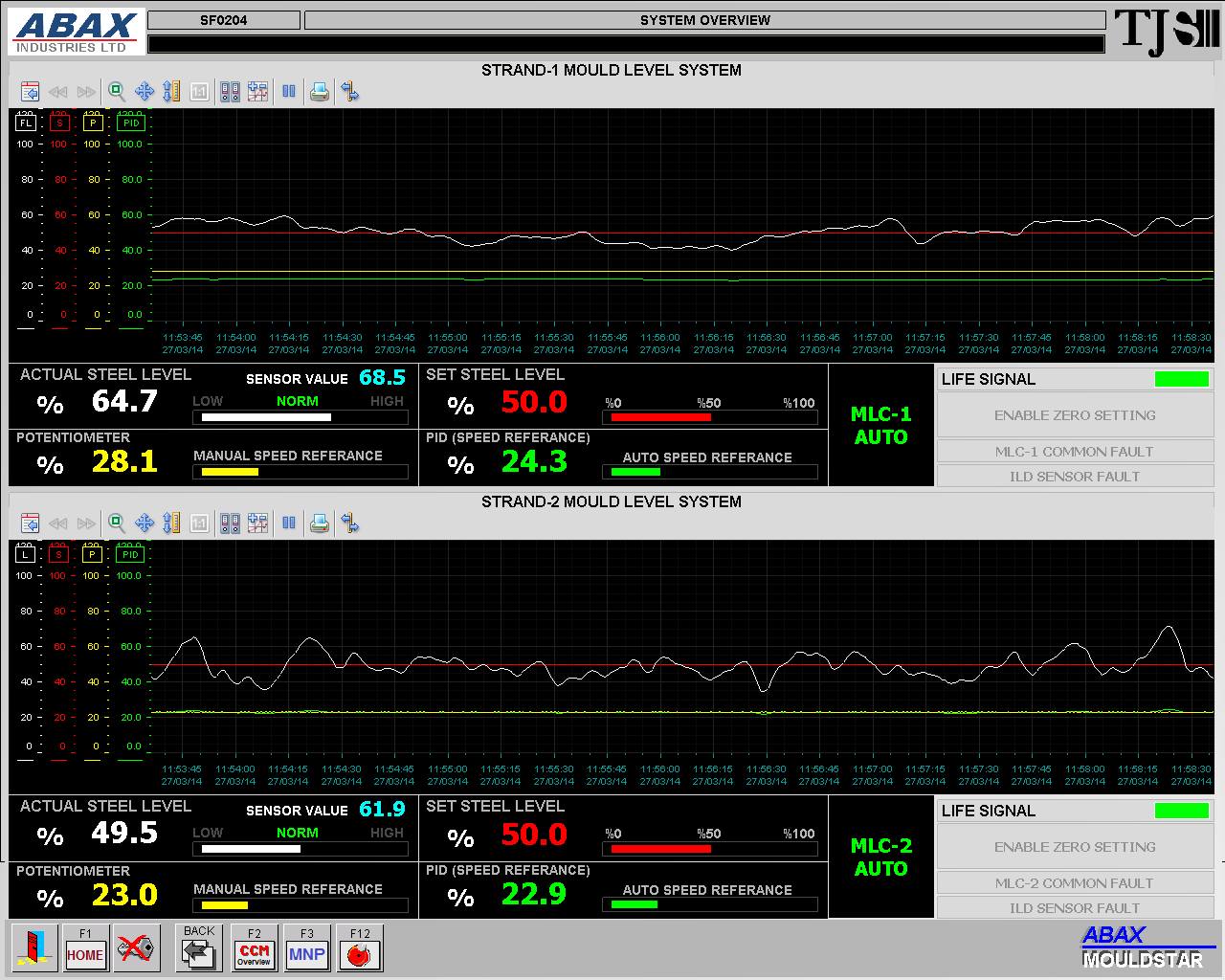

ABAX MouldStar®

ABAX MouldStar® Mould Level Control System can provide a high performance and non-radioactive level-control for moulds. It has been designed to improve the working conditions of the mould-operators and now the result is a system which has significant advantages if compared to any optic or radioactive level control on the market.

ABAX SprayStar®

ABAX SprayStar® Secondary Cooling Automation is particularly designed for billet casters. It provides the optimum thermal profile of the billet, considering changing casting conditions such as speed, steel-composition, superheat.

The following targets are achieved:

- Reduced variations of surface temperature

- Reduced temperature gradient in the billet section

- Precise billet temperature control before straightening

ABAX TubeStar®

ABAX TubeStar® Mould Tracking Automation is a special function of our standard billet caster automation. It allows to track and display all relevant data of each mould-tube in use. This new function is particularly important because it monitors the conditions and histories of all mould tubes, which are the most decisive variable of the casting process.

The following data are continuously monitored and recorded:

- Number of heats and cast tonnage

- Steel-grades of the cast heats

- Casting speed

- Heat extraction

- Primary cooling temperature difference

- Strand location

- Actual tube internal geometry measured with ABAX TaperStar®

ABAX TubeStar® is available also as stand-alone package and can be implemented on any casting machine which has a MMI-system.

ABAX ProcessStar®

ABAX ProcessStar® is the Level-II Production-Supervisor which has the task to guide the operators and process-engineers via a user-friendly interface and comprehensive reporting.

ABAX ProcessStar® has the following main functions:

- Storage of the casting recipes & setpoints

- Process data tracking & recording

- Billet quality prediction

- Heat & billet reports

- Equipment lifetime tracking