Continuous Casting Machines

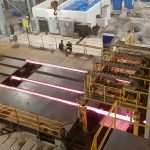

ABAX billet casters are capable to produce square, rectangular or round sections from 100 to 240 mm. Our modular equipment can be selected according to the requested steel-quality which can range from simple rebar to SBQ grades.

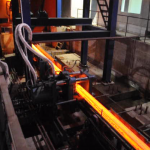

Various technological packages, such as Automatic Mould Level Control, Mould Electromagnetic Stirring (M-EMS), Strand & Final EMS and Stopper Flow Control are available and can be applied based on the specific requirements.

High-speed casting technology, which is based on the ABAX XXL-technology, has been successfully introduced. This technology is presently enabling to reach a strand-productivity of 45 t/hour of good quality billets without negative aspects on operation.

Our casters are equipped with advanced Level-1 and Level-2 automation systems which allow to get a maximum of data from the casting-process. We provide full automatic operation and computer aided control of the billet quality.

ABAX bloom casting equipment is operating at important European steelmakers producing sophisticated grades which are for instance used for high speed rails.

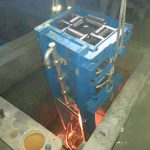

One of our advantages is that ABAX Group manufactures equipment as well as copper-moulds, which are the heart of any continuous casting machine.

Due to our daily experience and feedback as producer of copper-moulds, ABAX has a very detailed understanding of the metallurgical aspects. This helps us to constantly improve the design and effectiveness of our equipment and technology.